Hydraulic pumps are one of the most important component […]

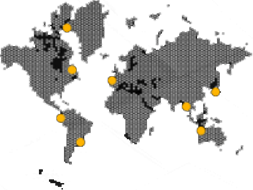

Hydraulic pumps are one of the most important components in an assortment of construction, manufacturing and machining equipment, especially in- construction machinery, agricultural machinery, mining equipment, marine operations and power transmission systems in heavy automobiles. The technological aspect is that a wide range of materials are used in hydraulic pumps to minimize wear and provide dependable performance.

The types of material used depend on the pressures and temperatures that the hydraulic system will encounter. Various plastics, synthetic rubbers and steel alloys are all used in the fabrication of hydraulic pumps. High-strength alloys and polymers are utilized in high-pressure systems.

Just as masking tape is used differently from most other types of tape, hydraulic pumps are differently from most other types of pumps. In most cases, fluid exiting a pump’s discharge doesn’t find its way back into the pump. This is what sump pumps, process pumps, and even medical pumps do. But even circulating pumps have a different role from hydraulic pumps. Circulating pumps simply keep a fluid in a closed circuit moving. That’s all.

Hydraulic motors are mechanical rotary actuators that convert hydraulic, or fluid energy into mechanical power. They are typically powered by gas or electricity and they work in tandem with a hydraulic pump, which converts mechanical power into fluid, or hydraulic power. Hydraulic motors provide the force and supply the motion to move an external load. These motors are available in various designs and with various specifications.

Hydraulic equipment uses pressurized fluid to generate power. The fluid used can be water or oil and the market is segmented on the basis of components into pump and motor, cylinder, valve, and others.

To promote fine management, sublimation of corporate culture as the goal, through the promotion of meticulous management, innovative thinking mode, through rational and moral edification tempered staff's mind, continue to expand the corporate culture, enrich the intrinsic enterprise, advocacy staff "hard work, thinking , Self-improvement, improve "spirit of enterprise.