With the increasing demand for energy-efficient product […]

With the increasing demand for energy-efficient products, the use of DC motors in ceiling fans and other household appliances also increased. DC motors and DC converters/drives are alive and well in industry, driven by many applications in which they are the best option. There are reasons why DC motors trump AC motors:

High Torque At Low Speed

Unlike an AC motor, a DC motor delivers constant torque across its entire speed range. Ceiling fans with DC motors create a higher torque, meaning greater initial power and less energy consumptions. DC motors consume 70% less energy than conventional ceiling fan motors. DC motors develop full torque at low speed and across the full operating range from zero to base speed.

Greater Control

DC motors control six speeds settings and reverse function. Generally, these motors are easier to start, stop, and accelerate.

Less electronics and rectification are required to build a DC-converter drive when compared to building an AC-inverter drive. DC motors can be directly fed from different power sources, even batteries.

Central Circuitry

Fans with DC motors have all the electrical components conveninently located in one place atop of the motor assembly, so there's no need for a canopy or switch cup. This makes wiring your ceiling fan during the installation process a lot easier.

Light Weight

DC motors generally weigh less than conventional fan motors, resulting in a lighter product that is easier to installed.

Quiet Operation

DC motors virtually silent, ensuring a quiet operation.

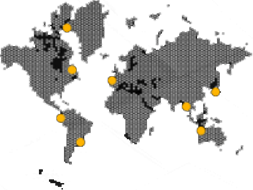

Applications

DC motors are suitable for many applications – including conveyors, turntables and others for which adjustable speed and constant or low-speed torque are required. They also work well in dynamic braking and reversing applications, which are common in many industrial machines.

To promote fine management, sublimation of corporate culture as the goal, through the promotion of meticulous management, innovative thinking mode, through rational and moral edification tempered staff's mind, continue to expand the corporate culture, enrich the intrinsic enterprise, advocacy staff "hard work, thinking , Self-improvement, improve "spirit of enterprise.